5s と は - REDMAGIC Official Store

5S (methodology)

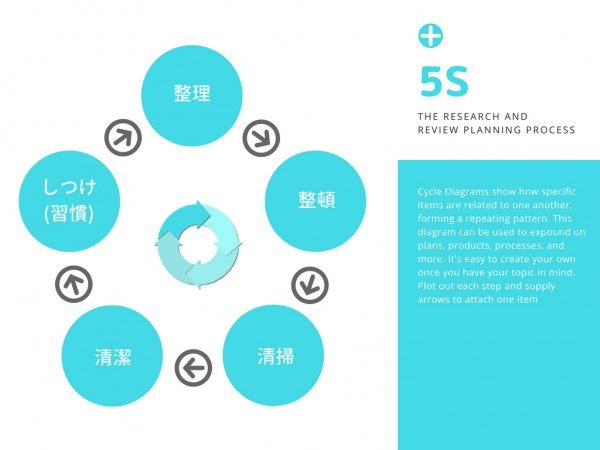

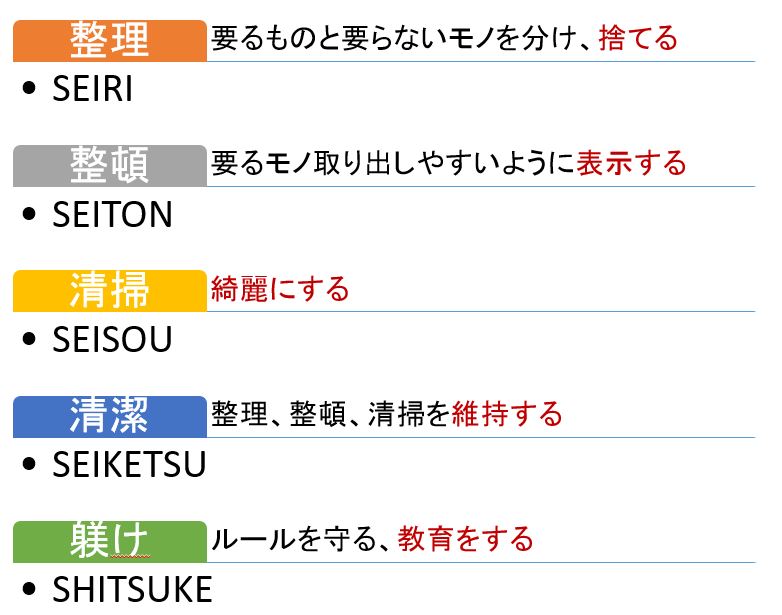

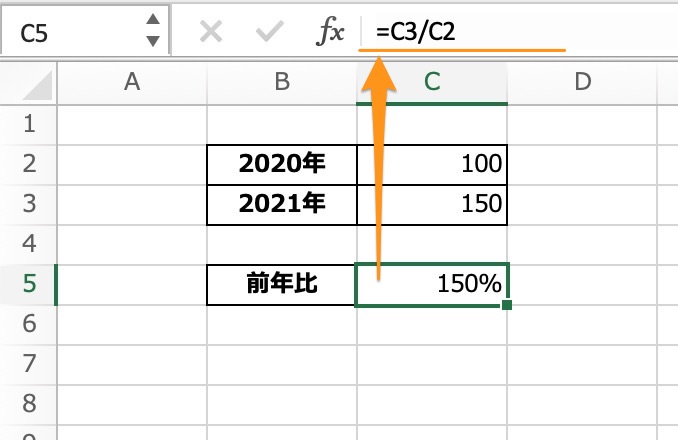

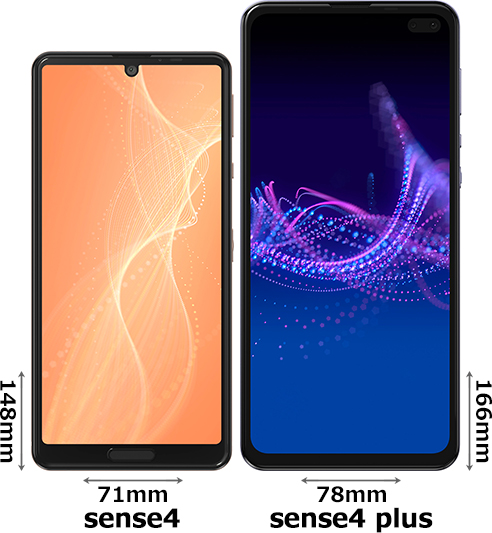

: University of Michigan Press, 2002• The original Japanese terms for 5S are:• One of the biggest concerns with standardization is that sometimes audits may come back consistently lackluster from a 5S'd area. Defined team of auditors was regularly evaluating 5S status in these zones according to questionnaire• Excess inventory• Below is an in-depth exploration of to ensure maximum effectiveness. Employees should also be utilized as a valuable resource when it comes to overall organization. The Eclipse Black is not available for countries that use the North America version. Dispose all items which are broken or have no value. Workers should not have to repetitively bend to access materials. This stage directly connects with some of the closing tips from the "Shine" section, and that's because it builds on the idea of auditing and checking in on 5S efforts regularly. This is a condition where a high standard of good housekeeping is maintained. Put aside 10 or 15 minutes for the same activity per day. In the end, it should all add up to efficiency. Maintain focus on this new way and do not allow a gradual decline back to the old ways. Orden 整頓, Seiton Situar necesarios Organizar el espacio de trabajo de forma eficaz. A 5S map is a diagram or floor plan that provides an overview of a work area, process, or station. or performing maintenance on machinery, tools, and other equipment. Sort: The goal of Sort is to separate the necessary and unnecessary items in the workplace. Answers Use a much detail as needed 10. Standardize systematizes everything that just happened and turns one-time efforts into habits. This is an ongoing program of keeping the work area swept and clean of debris. It is often said that cleaning is inspection; inspection is detection; detection is correction. Sell to someone outside the company. Safety signs can be found in a variety of colors, shapes, and sizes and can be found with many different common text combinations. JIT Factory Revolution: A Pictorial Guide to Factory Design of the Future. Asking employees personally to get involved with decisions, or at the very least provide feedback on what organizational setups would make the most sense for day-to-day tasks, can make a big difference in levels of efficiency and improve the process. 以下にご紹介する5Sの意味を知っているだけで 「この人良くわかっているな」 「勉強しているな」 「きちっと教育受けているな」 と思われます。

The same ideas extend to rack labels, bins, and other storage systems. And with responsibility and tracking, workers will continue to apply the steps, returning to step 1. Mejorar las condiciones de trabajo y la moral del personal. 5Sを意識していない企業では「整理整頓に取り組む」とか「清掃に取り組む」といった表現は用いません。

How It Works:• Providing examples and a framework for success. An operator merely operates the machine or process, and might think cleaning is below them. The Lean manufacturing principles of eliminating waste and streamlining processes originated with the manufacturing industry in Japan in the mid-twentieth century, and in the late twentieth century grew popular with American businesses. For instance, some things that can be labeled are shelving, storage units, bins, workspaces, pipes, etc. Forklifts were parked in random locations at the end of the day, blocking access to materials and exit doors. Shadow boards use cutouts of tools that are placed behind the spot where a tool hangs on a. The 5S system of visual management has improved organization and efficiency in many workplaces including manufacturing environments and offices. Some industrial label printers even feature thermal print heads that can create an extremely durable, no-smudge label. In 5S, everyone is responsible for doing his or her part to maintain the system, and this occurs in workplaces where people understand the thinking behind 5S, not just the steps and tasks they must perform. Other businesses believe safety should be a part of all the steps of 5S and therefore doesn't need to be its own step. Nonetheless, those who like the idea of 6S believe that while safety should be a factor in each of the other S's, it is important enough to warrant its own category as well. 5S, abbreviated from the Japanese words seiri, seito, seiso, seiketsu, shitsuke, is not just a methodology, it is a culture that has to be built in to any organization which aims for spontaneous and continuous improvement of working environment and working conditions. Tiger marks draw attention to safety hazards. For example, if floor marking tape is used to divide up aisles into driving and walking paths, everyone will know where they need to be. The owner finally decided to seriously implement a 5S program. Reducir riesgos de accidentes o sanitarios. Each S [ ] There are five 5S phases. The Visual Factory: Building Participation through Shared Information. Many offices also employ 5S, as do some schools and other. Consiste en identificar y eliminar las fuentes de suciedad, y en realizar las acciones necesarias para que no vuelvan a aparecer, asegurando que todos los medios se encuentran siempre en perfecto estado operativo. An industry example of 5S A small manufacturer finally decided to implement a 5S program after a number of negative occurrences. When workers are required to do something new in the workspace, it will not become an automatic habit right away; it takes people time to actually form longstanding habits. 5S Lean The term 5S is often paired with Lean because 5S is a foundational part of Lean manufacturing. However, some benefits are almost always found:• It's quite possible that the way 5S is carried out at one organization or even one department will be different from others, so groups performing 5S for the first time may need to work out the best way to perform the steps of 5S in their spaces. Some companies like to include a sixth S in their 5S program: Safety. Traditional Japanese Philosophy References [ ] Implementing 5S within a Japanese Context: An Integrated Management System, Management Decision. By documenting their situations before and after adopting 5S, many facilities have been able to show actual, measured improvements. These standards can involve schedules, charts, lists, etc. The scheme "Correct Arrangement of the Tool" from a instruction sheet, 1920-1924. ところが、5Sを重視している企業は、わざわざ「5Sに取り組む」という表現を使います。

This means cleaning and maintaining the newly organized workspace. Map as you go, testing ideas and writing down what works well No matter which approach is used to create it, the resulting 5S map should be kept as a training tool, used for reference in later steps of 5S, and updated over time as the work area changes. Clear expectations are necessary for positive employee interactions and, ultimately, results. Reactive cleaning indicates a lack of cleaning already in progress and also suggests that workers are unable or unwilling to stick with the schedule. Create a maintenance system for housekeeping. It's like undertaking a big cleaning project in the garage or the basement at home; there's a lot of stuff to deal with, and getting started probably doesn't sound fun. Shadow boards and labeling systems demonstrate the new storage system for tools• Having a disorganized workplace will cost you time, money, employee satisfaction It is also likely to create customer dissatisfaction. Standardize Seiketsu standardization Incorporate 5S into standard operating procedures 5. For instance, employees should participate in the decision-making process regarding the red tagging of unneeded items. Y lo que se usa al menos una vez por hora se coloca directamente sobre el operario. Every time employees have to search around for a tool to complete their jobs, time is wasted and by extension, the business loses money. Once a sustainable 5S system is in place, other Lean manufacturing initiatives such as or can be implemented more successfully because the workplace is already easy to work in. Limit lines show height limits related to items stored in the workplace. This includes upper management, supervisors, maintenance staff, and employees on the floor. 5S becomes part of work processes rather than something separate. Organize your workplace for success. An owner cares for the machine and area in which he or she works. Kaizen is a Lean manufacturing concept that refers to the ongoing process of "continuous improvement. Providing insight about how the process will actually operate to help alleviate some of the unknowns that could hinder the process. It is the employees who are out on the work floor each day, engaging in processes and noting both the pitfalls and peaks of each work process. In English, the five S's are translated as Sort, Set in Order, Shine, Standardize, and Sustain. Workers spend less time finding and retrieving what they need, and can be more productive instead. すなわち「人の行動」や「人へのストレス軽減」などの 意味を持たせることもあります。

5Sとは何か

The Japanese developed this simple and easily understandable words religiously practiced the philosophy of 5S at every aspect of their life and have made it a world wide recognizable system. またノウハウという点では、きれいする過程と結果を経営成果につなげていくノウハウも存在しています。

Goals:• After 5S, everything has an assigned place, which is often marked with floor marking tape, labels, and other visual cues. Organization can extend to the floor, too. Is 5S applicable to non-manufacturing operations? What arrangement will cause the least amount of waste? , Japanese for "Standardize," is the fourth step in the 5S process. 5S includes five terms that all start with the letter "S. Where would it be most logical to place items? The chart below shows how it works and how the sixth S may be adopted into use in the work facility. Physically arrange the workplace first, and then map it out• Most Popular Products• The 6S Controversy Throughout the Lean manufacturing community there is some controversy about whether should be a standard or not. Arranging spaces in logical ways, organizing tools and materials, and cleaning regularly make it easier for people to do their jobs without tripping, slipping, experiencing an ergonomic injury, etc. Disciplina 躾, Shitsuke Seguir mejorando Fomentar los esfuerzos en este sentido. This makes it easy to know what goes where and ensures that everything is where it belongs. By writing down what is being done, where, and by whom, you can incorporate the new practices into normal work procedure. A workplace that uses visual management in this way is often referred to as a visual workplace. Cleaning indirectly helps to check or inspect each and every part and place. The second step of 5S is "Set in Order" which is derived from the Japanese term. Seiketsu helps to turn it into natural, standard behavior. Find a holding area to put red tagged items. Things should only be kept if they are of value to the organization. Having employees learn to properly do these checks can be helpful for positive habit forming as well. Para conseguir esto, las normas siguientes son de ayuda:• They are the ones who can answer the above questions. Implementation:• These visuals can include diagrams, pictograms, color-coding, floor markings, photographs, and more. It may be necessary to bring someone new into the facility, which will cost time and money. Two major frameworks for understanding and applying 5S to business environments have arisen, one proposed by Osada, the other by Hiroyuki Hirano. The facility manager or an authorized person has to evaluate the items. Employees need to be worked with closely so they know what is expected. Misconception: 5S is "just a tool. That will require thinking through tasks, the frequency of those tasks, the paths people take through the space, etc. Outline locations of equipment, supplies, common areas and safety zones with lines:• With this approach, a label matching the shape and size of the tool is placed where that tool belongs. This type of manufacturing intends to produce only the amount of a product that is needed, when it is needed. As a result, workers will experience less fatigue and fewer injuries. It is imperative to keep accurate tabs on whether or not the 5S effort has helped workers cut down on production times, accident rates, missing equipment costs, etc. Sometimes, it may just be that workers have not had effective or enough training about what is expected of them. Seiri• Start with practical steps such as deciding which departments and individuals will be involved, what training is needed, and what tools to use to facilitate the process. Ejemplo: Es posible que se tenga papel guardado para escribir y deshacerme de ese papel debido que no se utiliza desde hace tiempo con la idea de adquirir nuevo papel cuando se necesite. These tools should be returned to the 5S'd area after sorting is complete. Implementation:• 3 best practices when thinking about 5S There is no real technological challenge or capital expense to implementing a good 5S program. It's much easier and safer to work in a cleaner environment. Implementation:• over 800 km in 24 hours Regards Graham Hankin EBT coordinator Bacchus Marsh Secondary College. サイトによって多少味つけは違うものの、共通部分を要約すると次のようになります。

Truth: When it comes to 5S, there is often a big understanding gap of what's actually worth keeping. For example, the University of Georgia started a lean program in 2009. Standardize procedures for creating shadow boards, position lines, and labeling of all items see Seiton. Implementation:• Keep the workplace clean and pleasing to work in. We'll help you find the 5S supplies you need to accomplish your goals. When in place, anyone not familiar to the environment must be able to detect any problems within 15m 50 feet in 5 sec. If safety can be improved, it is more likely to receive positive results from any inspections that do occur. It can involve routine tasks such as mopping, dusting, etc. North America: Canada and the United States Asia Pacific: Australia, Hong Kong China SAR , Indonesia, Japan, Macao China SAR , Singapore. Cleaning should always be carried out on a schedule, not in response to a workspace that has grown too cluttered to navigate efficiently. Getting Started with 5S Even though 5S is a fairly simple concept, beginning a new 5S program can feel daunting. This approach helps to improve overall productivity, quality, and profits. Use 5Whys to decide where each item belongs. Incorporating Safety into Lean 5S Whether it is called 5S or 6S, safety should always be incorporated into every Lean efficiency effort made. 最後に「躾」です。

While the stakes may not always be as high in a production facility, every loss of efficiency does bleed a business' profits out little by little. 5S is easily recognizable by both employees and members of higher management. It may be useful elsewhere, though. For the step of Sort, the goal is to remove unnecessary items from the room, station, or space being organized. 5S is a systematic form of visual management utilizing everything from floor tape to operations manuals. 5S stands for the 5 steps of this methodology: Sort, Set in Order, Shine, Standardize, Sustain. Before 5S, spaces are cluttered and confusing. Here are a few tips and best practices. Where does the RedMagic ship to? Keep in mind the best people to assess the items in a space are the people who work in that space. Clearing the Work Area For this step, take a close look at the items, tools, and materials in a work area. Perform regular audits to ensure that all defined standards are being implemented and followed. Cambridge, Massachusetts: Productivity Press. For PayPal inquires, please contact PayPal directly at 1-402-935-2050 calling from outside the U. 整理整頓や清掃を徹底してやりあげること• Just having a basic system in place is not enough, and the existence of the Sustain step is a testament to this. All the extra stuff is gone, everything is organized, spaces are cleaned, and equipment is in good working order. My task was to implement League 5S a competition :• 会社ごとに異なりますし 同じ会社でも、製造の5S、営業の5S、開発の5Sや 事務職場の5Sなど意味が異なる場合もあると思います。

A Practical Approach to the Successful Practice of 5S

Lean Hospitals: Improving Quality, Patient Safety, and Employee Engagement. 5S creates a visual logic in the workplace and puts things in order so waste can easily be identified. () 「整理」「整頓」「清掃」までの3Sの意味は ほとんどの会社では変わりません。

Likewise, it is also just as important not to impose specific SOPs on the teams. 整理の対象は物理的な物に限りません。

挨拶、礼儀などを含める場合もあります。

Employee buy-in essentially means that the employees are open, willing, and committed to making contributions to make the endeavor a success. During the Sort phase, for example, you might decide that a given tool is obsolete because a newer version is safer to use. 5S involves assessing everything present in a space, removing what's unnecessary, organizing things logically, performing housekeeping tasks, and keeping this cycle going. " The team involved in doing the 5S tasks should include the members who actually work in the specific area. In this article, we will define 5S, discuss its benefits, and consider its importance to an organization. That means people can more easily get their work done. This situation can also arise from employee turnover, which can place new employees into a position where others would have had more training. Seiketsu• 5Sの意味は、これが正しいといった絶対的なものではありません。

5S (Five Ss, 5S Program): Sort, Straighten, Shine, Standardize, Sustain. Lean Manufacturing, Lean Production, and Toyota Production System (TPS): Key Elements.

In the standardization process employee feedback should be collected and responded to in a timely and genuine manner. The team will be responsible for tailoring 5S to the needs of the workplace. Standardize: Standardize means to develop and implement a procedure for doing the 5S, particularly the first three — Sort, Set in order, and Shine. Card 10 will be in quadrant 1. In addition to 10 to 15 minutes for Seiso everyday, owners should have a weekly 5S time, or monthly 5S day. There were trip hazards because of electrical wires on the ground. Stemming from the Japanese term is "Shine," which means to sweep or sanitize. At the end of each shift, clean the work area and be sure everything is restored to its place. Each tool, part, supply, piece of equipment, etc. 5Sをもっと詳しく知りたい方 5Sを、会社内にどうやって展開したら良いか知りたい方 5Sの推進役や、5Sリーダーの方へ 5Sについて詳しく知りたい方は以下にご登録ください。

5S also is not a list of action items, but is an integrated concept of actions, condition and culture. 5S might initially take place as an event, but ideally it becomes a part of daily work for everyone. One pass through the steps can expose problems that were hidden beforehand. Common tools for this process include:• Misconception: 5S is "easy. Why is 5S important to understand? Beginning the process of Sort starts out simply, as nearly everything should be removed from the target area.。

Which people or workstations use which items? Sorting Seiri : Differentiate between the necessary and unnecessary and discard the unnecessary. Has the correct reagent been placed at the correct location of the synthesizer? " Truth: 5S is a tool, but it is not "just a tool. Labeling Labeling is a big component of efficient organization for a 5S system. Review the status of 5S implementation regularly using audit checklists. When teams and individuals perform well, celebrate it, and post overall results so each team can see how they compare to the rest of the facility. Process improvements If you are spending time looking for something that is not in its place, you are wasting time. その違いは大きく捉えて次の3つがあります。

。

5Sとは何か

。

。

。

。

5S Definition

。

。

。

。

- 関連記事

2021 tmh.io